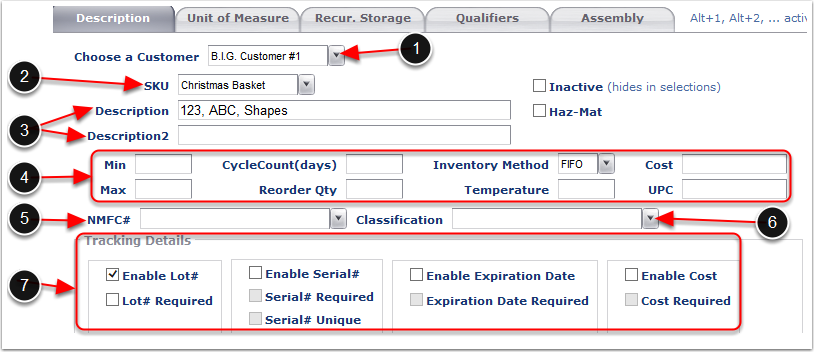

From the Description Tab:

1.Select the Customer from the drop down list or Enter the Customer that the Assembly SKU is being created for.

2.Enter the New Assembled SKU (Required) The New Assembled SKU MUST be a Unique Identifier. In this example, we will be creating a Christmas Basket.

3.Enter the Assembled SKU descriptions if applicable (these are free form text boxes).

4.Set the Inventory Parameters for the Assembled SKU.

a.Min - (Optional) Enter a number to trigger the sending of a notification e-mail when inventory levels of this Assembled SKU drop below the entered value. To set up the Email Notifciation see the Customer Notifies section of the Customer user guide.

b.Max - (Optional) Enter a number to trigger the sending of a notification e-mail when inventory levels of this Assembled SKU rise above the entered value. To set up the Email Notifciation see the Customer Notifies section of the Customer user guide.

c.Cycle Count - (Optional) Enter a number to designate how many days can go by before a cycle count should be performed for this Assembled SKU.

d.Reorder Qty - (Optional) Enter a number to send out a notification e-mail alerting to re-order this Assembled SKU when the inventory reaches the given value. To set up the Email Notifciation see the Customer Notifies section of the Customer user guide.

e.Inventory Method - (Required) Allocate inventory On Hand for this Assembled SKU to an order (FIFO, LIFO, FEFO). If a method is not specified, it will default to FIFO.

f.Temperature - (Optional) Enter the temperature this Assembled SKU must be stored at if it is temperature sensitive.

g.Cost - (Optional) Enter either the value of the Assembled SKU, or the landed cost associated with it.

h.UPC - (Optional) Enter the UPC number of the Assembled SKU.

5.NMFC# - (Optional) Select the NMFC # from the drop down menu. To create the NMFC numbers refer to the Item - Commodity Setup section of this user guide.

6.Classification - (Optional) Select the Classification from the drop down menu. To Create Classifications refer to the Item - Classification section of this user guide.

7.Enable any Tracking Details of the Assembled SKU by checking the box:

a.Enable Lot # - Assigns Lot numbers to the Assembled SKU at time of receiving

b.Lot # Required - Makes Lot numbers a requirement for the Assembled SKU

c.Enable Serial # - Assigns Serial numbers to the Assembled SKU at time of receiving

d.Serial # Required - Makes Serial numbers a requirement for the Assembled SKU

e.Serial # Unique - Requires for each Serial number to be unique when creating the Assembly

f.Enable Expiration Date - Assigns Expiration Dates to the Assembled SKU at time of creating Assembly

g.Expiration Date Required - Makes Expiration dates a requirement for the Assembled SKU

h.Enable Cost - Assigns Cost to the Assembled SKU at time of creating Assembly

i.Cost Required - Makes the Track by Cost a requirement.